Recently, according to an official announcement from the Institute of Bioenergy and Processes at the Chinese Academy of Sciences in Qingdao, the institute has successfully overcome the final hurdle in the production process of large-scale solid-state batteries for vehicles using sulfide materials. They have also achieved a critical breakthrough in the technology of sulfide pouch cell stacking.

As the core technology for the next generation of power batteries, solid-state batteries have been attracting significant attention. Solid-state batteries offer advantages such as high safety, good stability, and high energy density, addressing issues like short lifespan, flammability, and explosiveness associated with traditional organic electrolyte batteries.

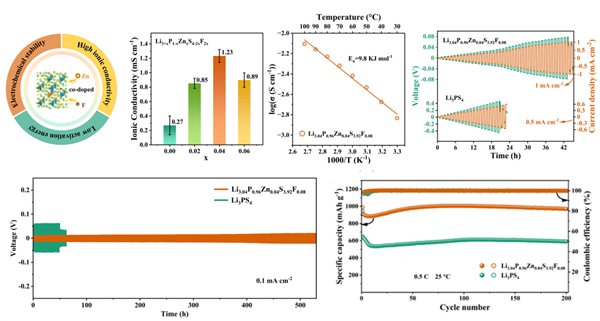

Among them, sulfide-based solid-state lithium batteries possess high energy density and high-rate performance, making them the optimal choice for electric vehicle power sources. Consequently, they have garnered attention and investment from major global automakers, with related mass production plans being announced.

According to reports, the institute’s Advanced Energy Storage Materials and Technology Research Group has successfully produced multi-layer pouch cell batteries. After 300 cycles of testing, the capacity of these batteries has shown virtually no degradation.

Additionally, the institute is accelerating the research and validation process of the technology, aiming to achieve mass production of sulfide-based solid-state batteries by 2026. Currently, the Institute of Energy Research in Qingdao has established a pilot production line for solid-state batteries and has successfully developed high-voltage, long-life pouch-type solid-state lithium-ion batteries.

After 1000 cycles of testing, these batteries still maintain a capacity of 92%. The batteries are currently undergoing further testing to meet the discharge capacity requirements at a 4C rate (according to Toyota’s standards, which require 1500 cycles with a capacity retention of 80%).